TECHNOLOGIES

Rotomolded polyethylene kayaks

Our rotomolded Polyethylene (PE) kayaks are made in a single layer or 3-layer HDPE. Plastic (polyethylene) powder is poured into a mold, heated and rotated to form a complete, one-piece kayak. For sea kayak models we use 3-layer HDPE lay-up to enhanced durability and stiffness. 1-layer HDPE lay-up is used in Ormen recreational kayaks, it's made using only a single layer of high density polyethylene that makes it very stiff and durable, yet it is lighter than the other 2- or 3-layer constructions. All the kayaks are made in our factory in Viimsi, Estonia.

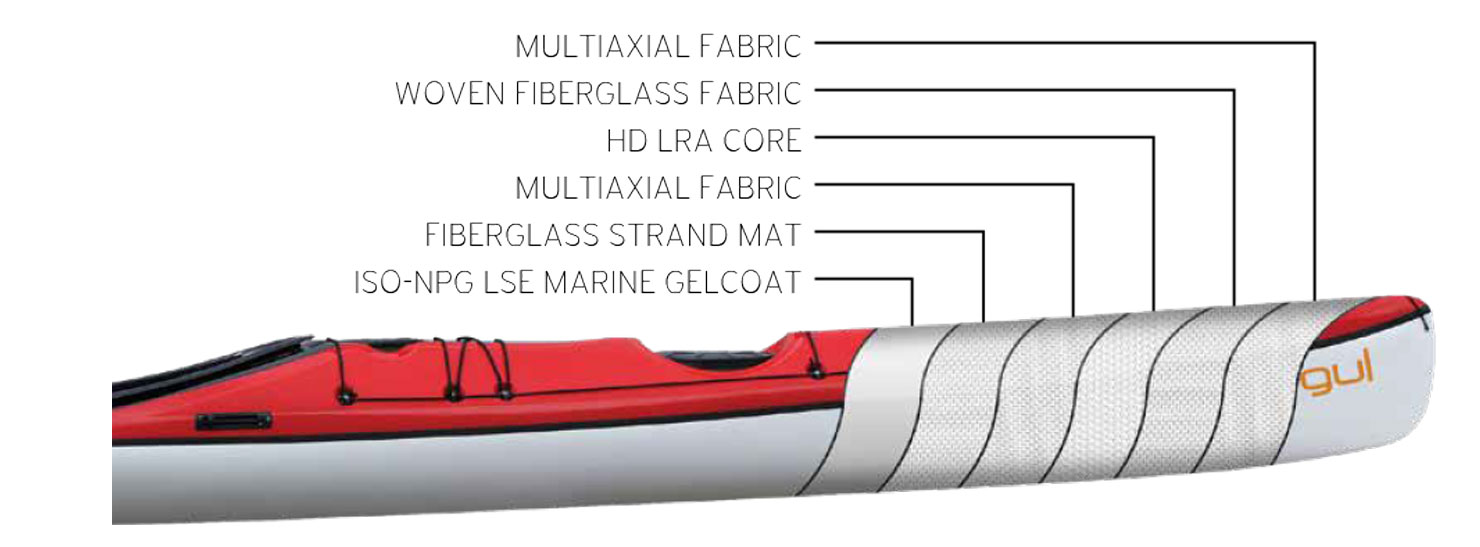

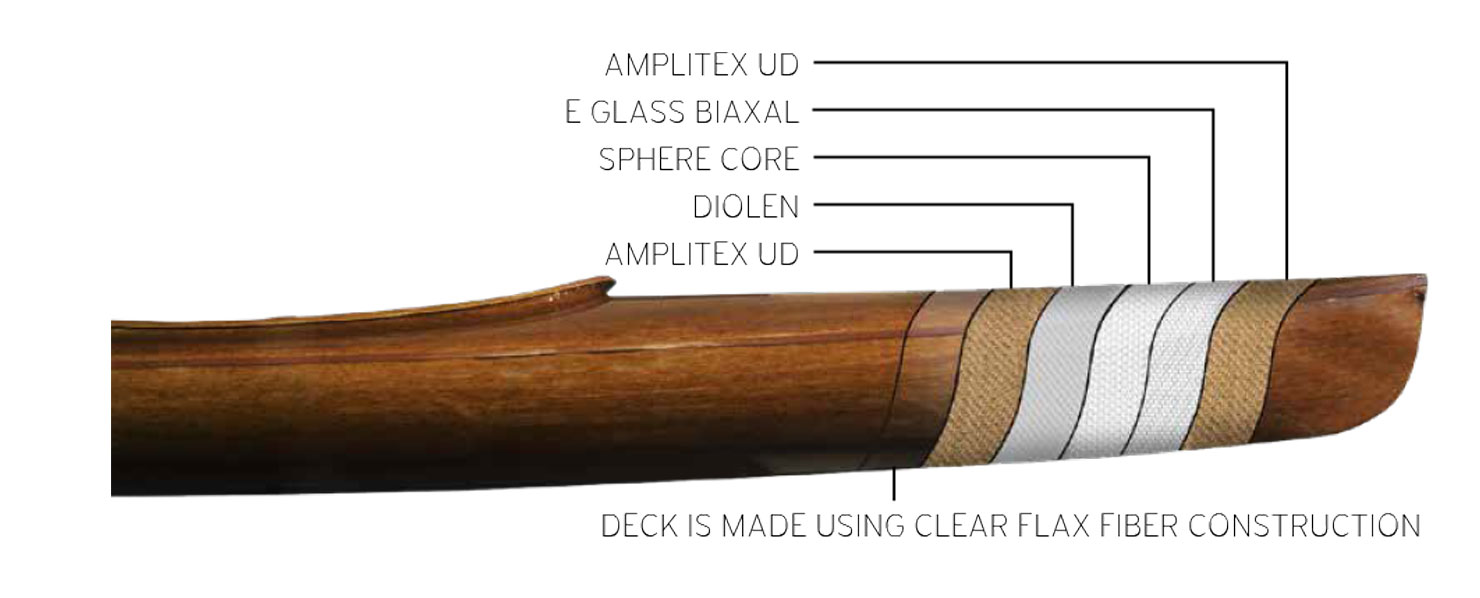

Composite construction kayaks

Composite construction type kayaks are the perfect choice for sea kayaking, then the weight and stiffness are important. Composite kayaks are handmade from different fiberglass/carbon fabrics that are held together by a special marine grade epoxy resin and with a help of vacuum technology it ensures the best weight/strength ratio. All Zegul composite kayaks are handcrafted in our factory in Viimsi, Estonia. *Please note that weights of the kayaks may vary +/- 2 kg (4 lbs) due to manufacturing processes.